Research Projects

1. Role of adhesion on the properties of elastomer-plastic & elastomer – fiber composites.1986 (Sponsor : DST, New Delhi)

2. Tearing, fatigue & abrasion of carbon black filled rubber. 1987 (Sponsor : Phillips Carbon Black Ltd., Durgapur)

3.Development of tank track pads & studies of their wear resistance. 1990 (Sponsor : DRDO, New Delhi)

4.Band formation behaviour of rubber & rubber blends during milling.1990 (Sponsor : CSIR, New Delhi)

5.Development of heat shrinkable and radiation crosslinkable materials for cable application. 1990 (Sponsor : BARC, Mumbai)

6.Studies of heat development and fatigue properties of rubberised road wheel compounds and development of rubberised road wheel.1995 (Sponsor : DRDO, New Delhi)

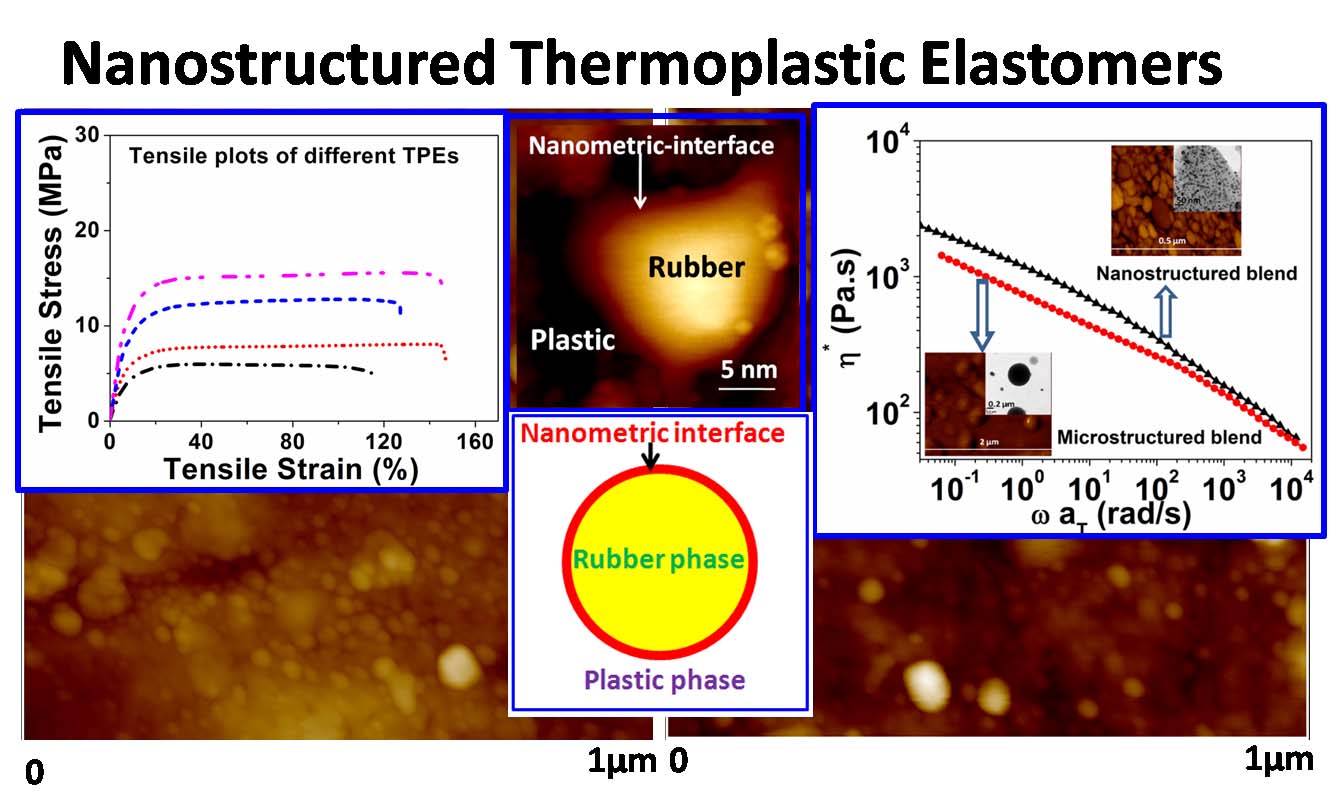

7.Development and properties of oil & heat resistant novel thermoplastic elastomers from rubber-plastic blends.1996 (Sponsor : DST, New Delhi)

8.Crosslinking and surface modification of elastomers using electron beam irradiation. 1999 (Sponsor : DAE, Mumbai)

9.Radiation Processing of Filled Elastomers & Plastic Using Electron Beam Accelerator. 2003 (Sponsor : DAE, Mumbai)

10.Development of Thermoplastic Elastomers from Rubber-Plastics Blends for Better Weatherability. 1999 (Sponsor : DST, New Delhi)

11.Development of electron beam radiation crosslinked high performance plastics from engineering plastics. 1999 (Sponsor : BRNS, DAE, Mumbai)

12.Chemical Devulcanization of Rubber and Recycling of Rubber Scraps and Wastes. 2004 (Sponsor : Ministry of Environmental & Forests, New Delhi)

13.Crosslinking of Ethylene Based Copolymers by Electron Beam Irradiation. 2002 (Sponsor : NICCO Corporation Ltd., Kolkata)

14.Development of nano-composite rubbers and studies of reinforcement mechanism. 2003 (Sponsor : DRDO, New Delhi)

15.Development of polymer based nanocomposites. 2003 (Sponsor : MHRD, New Delhi)

16.Development and properties of polymer based Nanocomposites, 2001 (Sponsor : DST, New Delhi)

17.Blends of Brominated Isobutylene-Co-Para-Methyl Styrene (BIMS) with Other Polymers. 2003 (Sponsor : Exxon Chemical Co., USA)

18.Novel rubber based nanocomposites using nanofibers and nanographites : development, structure and properties , 2004 (Sponsor : DRDO, New Delhi)

19.Development of novel applications using electron beam irradiation : (i) improved extrudability of raw and waste polymers, (ii) adhesion improvement of polymer composite, 2005 (Sponsor : DAE, Mumbai)

20. Tack and cured adhesion of brominated isobutylene paramethyl styrene with other rubbers , 2005 (Sponsor: Exxonmobil Co. India Pvt. Ltd., Mumbai)

21.Study on modification and properties of thiol terminated liquid polymers & polyurethane polymers by chemical reaction with nanostructured functional materials and nanosilica for space applications , 2006 (Sponsor: ISRO, Bangalore)

22.Fundamental studies on improvement of ageing and degradation resistance of hydrogenated nitrile rubber, 2007( Sponsor: LanXess, Germany)

23.Fundamental studies on structure and properties of nanocomposite rubbers for Tire Applications, 2006 (Sponsor : Goodyear Tire and Rubber Company, Ohio, USA ).

24.Nanocomposites for electronics, light yet strong engineering applications, coating fuel cell and clean energy , 2010 (Indo-Australia project)

25.Preparation and characterization of rubber nanocomposites, Bridgestone Corporation, Japan, 2014

26.From fundamentals to applications of nanoparticles assemlies , 2014, Indo-US project with the University of Houston and Columbia University, USA

27.Study on the improvement of heat resistance and mechanical strength of DENKA ER, 2015, DENKA Corporation, Japan

28.Frontier methods of preparation and characterization of rubber nanocomposites, 2014, Bridgestone Corporation, Japan

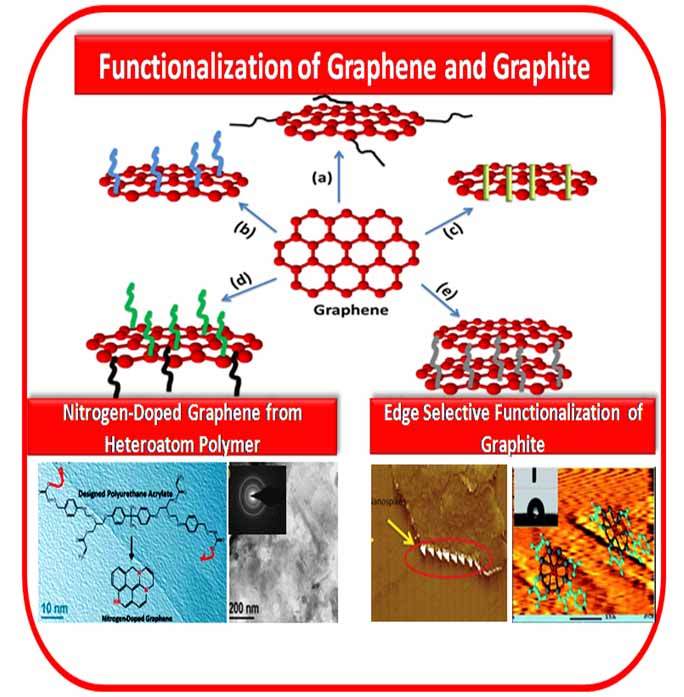

29.Development of natural graphite and graphene based rubber compositions for tyre and non tyre applications , 2015, BIRLA CARBON

30.Development of advanced polymeric materials, 2016, Bridgestone Corporation, Japan

31.Development of High Performance Rubber Composites using New Generation Materials for Application in Tyre, 2017, Ucchatar Aviskar Yojana , MHRD, Govt. of India

32. Design and development of silica analogues for synthetic rubber reinforcement , Reliance Industries Ltd. 2017

33. Effect of High Pressure and High Temperature on The Degradation of Fluoroelastomer Vulcanizates, 2019, Schlumberger

34. Development of Advanced Polymer Processing and Characterization Facility for Enabling Materials Research Towards Sustainable Communities and Infrastructure, 2020, University of Houston

35. Effect of High Pressure and High Temperature on The Degradation of Fluoroelastomer Vulcanizates, 2021, Schlumberger

36. High Pressure Experiments with Polymers: Sorption of Gases and Devulcanization of Waste/Aged Polymers, 2023, Schlumberger

37. Investigations on Durability of Elastomers at High Pressure and High Temperature, 2023, Halliburton

Consultancy Projects

- Development of pressure sensitive adhesive tapes – Supersilk Products, Kharagpur

- Development of rubber seals & diaphragms – P.K. Enterprise, Calcutta.

- Development of rubber solution for rubber repair – Dey’s Chemical, Kharagpur

- Development of return idler and impact idler – TRF, Jamshedpur

- Development of adhesive for concrete to concrete joints – Anuvi Chemical, Mumbai

- Development of rubberised rail pad – D.K. Steel, Calcutta

- Development of special tyre flap – Hercules Polymer Ltd., Asansol

- Development of flue duct expansion joints – K.E. Burgemann Fiber India Pvt. Ltd., Chennai

- Development of pinch roller and belt for tape deck recorder – Packwell Indutries Ltd., Delhi

- Development of rubber ground pad – Packwell Indutries Ltd., Delhi

- Development of low loss rubber compounds for conveyor belt – Phoenix Yule Ltd., Kalyani

- Analysis of a failure hose samples Pix Transmission Ltd., – Nagpur

- Development of polymer blend Packwell Industries, – New Delhi

- Analysis of elastomeric bridge bearings METCO, – Kolkata

- Development of cycle tube puncture solution Sun Rubber Industries, – Madurai

- Mechanical analysis of samples Phoenix Yule Ltd., – Kalyani, West Bengal

- Advise on cable compound , NICCO Corporation Ltd., – Kolkata

- Polymer analysis and formulation development MGM Rubber Co., – Kolkata

- Evaluation of steel wire Pix Transmissions Ltd., – Nagpur

- Testing of EPDM rubber based test slabs and test buttons MGM Rubber Co., – Kolkata

- Development of rubber & polymer clad rolls at cold rolling mill complex of TATA steel TATA Steel, – Jamshedpur

- Development of polymer blends, Phase-I Sethia Finance & Trading Co., – New Delhi

- Analysis of bumper polymer TATA Steel, Jamshedpur

- Identification of rubber sample supplied M/s PIX Transmissions Ltd., – Nagpur

- Analysis of elastomeric bearing Second Viveka-nanda Bridge Tollway Co. Pvt. Ltd., Kolkata

- Studies of the technical requirements of elastomeric inflatable seals, IGCAR, Kalpakkam

- Analysis of Rubber Compound Tega Industries Ltd., Barapukur

- Chemical and physical properties of rubber Office of the Commissioner of Customs Kolkata

- Utilization of waste rubber Elin Electronics Ltd., New Delhi

- Estimation of contact angle and surface energy, INARCO LTD. Gujarat

- Development of fire resistant energy optimized belt Phoenix Yule Limited, Kolkata

- Thermoplastic elastomers GE Industrial Plastics, Bangalore

- Ageing, failure analysis and life estimation of rubber seals of military aircraft (LERS) Regional Center for Military Airworthiness, Ministry of Defence, Nasik

- Control of Mooney Viscosity of Devulcanized Rubber, SE Power, Vadodara, Gujrat

- Development of improved adhesive system for ultra heat resistance conveyor belts used at high temperature , TATA STEEL

- Influence of haritsil filler in rubber compounds , Haritson Ltd.

- Advanced rubber compounds for tyre, JK TYRE

- Development of rubber clad rolls used in the PLTCM and the ECL sections of the cold rolling mill complex , TATA STEEL

- Joint life improvement of the conveyor belts being used in Tata Steel, TATA STEEL

- Development of thermoplastic elastomers from waste, Packwell Industries Ltd.

- Development of Improved Rubber Compounds in Cold Rolling Mill Complex TATA STEEL, Jamshedpur